The quality of fuel is vital to the efficiency and performance of engines. In time diesel fuel may become polluted by impurities including water, sediment and microbial growth which could adversely impact the engine’s performance and cause costly repairs. Fuel polishing can be used to prevent fuel contamination and ensure the smooth operation of engines.

Polishing of fuel, also referred to as diesel fuel polishing, is a procedure that involves removing contaminants and impurities from diesel fuel. Professionals make use of advanced equipment and techniques to restore the fuel to its best condition. Polishing fuel can improve the performance of engines it reduces maintenance costs and extends the longevity of equipment by eliminating harmful substances and making sure that the fuel’s quality is restored.

Numerous fuel polishing services are available to cater to the varied requirements of various industries that depend on diesel fuel. They employ highly trained technicians who are specialists in fuel systems and have a thorough understanding of the intricate issues that arise from contamination of fuel. Their expertise in depth and the use of specialized tools enable them to identify issues related to fuel and employ the right methods to polish fuel.

Fuel polishing’s main goal is to get rid of contaminants like sediment, water, sludge or microbial contamination from diesel fuel. It is possible for water to build up in fuel tanks as a result of leakage or condensation. This leads to corrosion, degradation of fuel and the development of bacteria and fungi. Sludge or sediment could be the result of impurities inside the fuel, or by the gradual degradation of fuel components. The contaminants can block filters and injectors as well as other important components. This could lead to lower engine performance or even a failure.

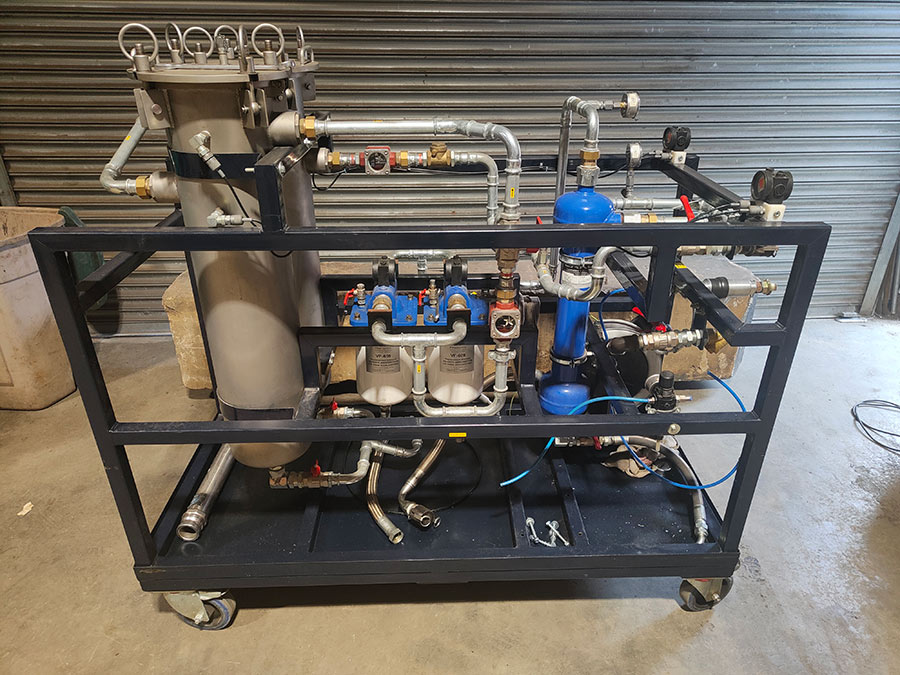

Fuel polishing typically involves a multi-step process. It starts with a fuel sample and analysis to assess the level of contamination to decide on the best plan of action. Following the analysis, technicians use filtering systems to remove impurities and contaminants from the fuel. These systems use a variety of filter media and technologies to effectively remove and separate pollutants from fuel, leaving clean and purified diesel.

Regular fuel polishing offers several key benefits. It increases the quality of the fuel and ensures that engines get regular, clean fuel for optimal combustion. This is, in turn, increases the efficiency of fuel and performance which results in cost savings and lower emissions. In addition, polishing the fuel helps lower the likelihood of engine failure as well as damage because of contamination of fuel. By eliminating harmful substances, polishing helps to maintain the integrity of the engine’s components, prolonging their lifespan and reducing the frequency of repairs and downtime.

Polishing diesel is a common procedure that has many advantages in order to preserve the quality of your fuel. First, it helps get rid of contaminants like water, sediments, and microorganisms, which could adversely impact engine performance. In removing these impurities via the process of diesel polishing, fuel quality is significantly enhanced. This improves the efficiency of combustion, leading to increased fuel efficiency and lower emissions. Second, regular diesel polishing keeps fuel filters from getting blocked injectors, filters, and other vital components, reducing the possibility of engine damage and expensive repairs. Regularly cleaning the fuel system also ensures that fuel storage systems last longer, by preventing the accumulation of corrosion and sludge. Regular diesel polishing or cleaning of the fuel can improve the efficiency of engines and cut cost. It also increases the efficiency of equipment.

Fuel polishing is also tailored to meet the demands of different industries and application. Fuel polishing can be applied to a range of applications, ranging from vessels for marine and backup engines, to construction equipment and transportation fleets. The process of polishing fuel is crucial for businesses that rely on an continuous and reliable power supply. It’s also vital when working in harsh, remote conditions, where the quality of fuel is a risk.

In short, polishing the fuel is a vital process that helps ensure the purity and purity of diesel fuel. By eliminating impurities and contaminants and reducing engine efficiency, it increases the effectiveness of the engine also reduces the costs of maintenance and increases the lifespan of the equipment. Through investing in a professional approach to polishing their fuel, companies can protect their operations, enhance performance and reduce the risk that comes with contamination of the fuel. Also, whether you’re managing the fleet of vehicles you own or operate critical power systems think about the advantages of polishing your fuel to unleash the full potential of your diesel fuel and drive your business forward.

Leave a Reply